Sensors

Application Specific Sensors

Purpose built pressure measurement + mapping sensor systems

A range of tactile sensors specifically made for unique, tough to tackle applications such as body pressure mapping, medical devices, and semiconductor and spray.

Quick Links:

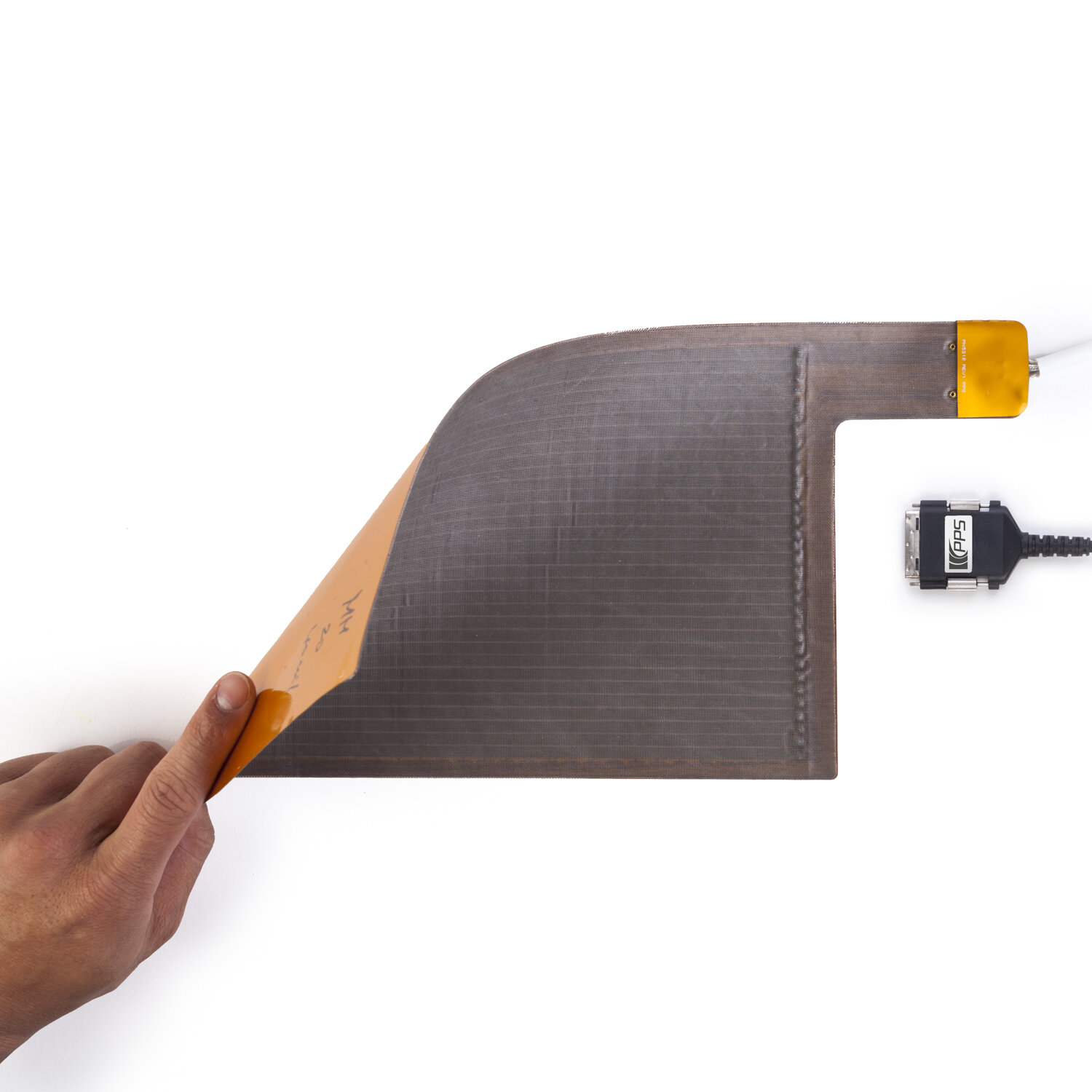

The TactArray Tactile Pressure Sensor

A configurable, high-resolution sensor fitting for most applications

TactArrays are our flagship pressure mapping sensors and cover a larger area than DigiTacts. Designed to perform in even the most complex situations. Available in many configurations.

Quick Links:

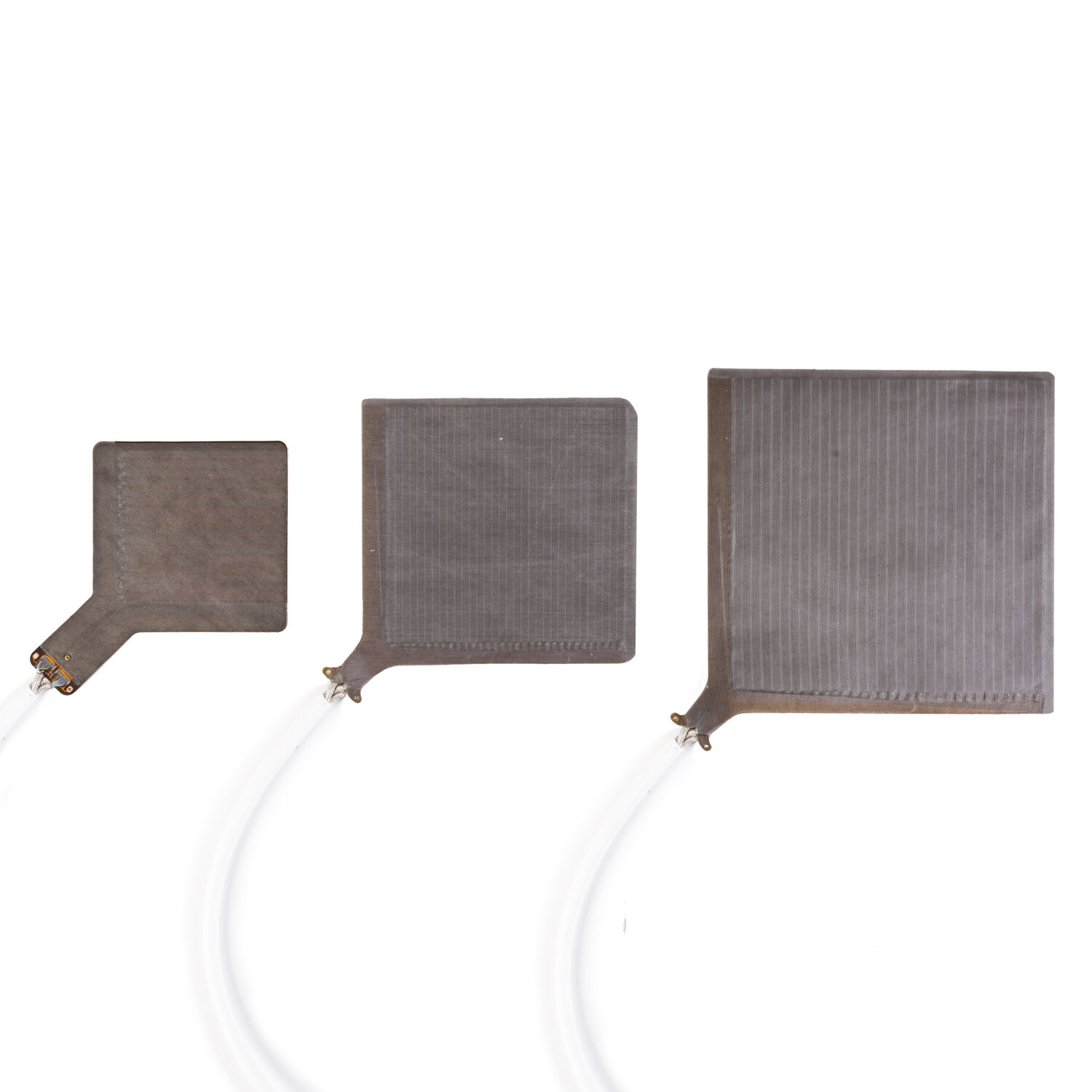

The DigiTact Pressure Sensor

A sensor made for smaller, precise applications

DigiTact sensors contain a small number (12-24) of discrete sensing elements with a common ground electrode. DigiTacts are best used for testing across smaller areas, embedding, and OEM integration. DigiTacts are available in many sizes and pressure ranges.

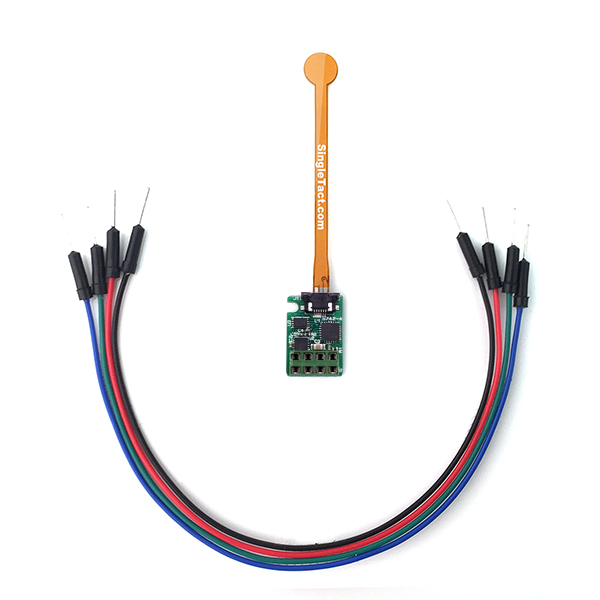

The SingleTact Pressure Sensor

An inexpensive, single point contact pressure sensor

The SingleTact is our most inexpensive sensor and can be purchased right away. For single points of contact or applications where only one sensing element is required, SingleTacts are the way to go. Available in multiple variations, and can be connected to create multiple sensing elements.

Quick Links: