White Papers

Interpreting TactileGlove Data for Practical Use Cases

This white paper provides guidance on understanding data collected by the PPS TactileGlove sensor, particularly in basic gripping and lifting tasks. It covers what to expect, how well the sensor performs, ways to reduce errors, and how to accurately interpret force and pressure readings.

The PPS TactileGlove is an advanced tool for testing ergonomics, offering precise measurements of hand pressure during various activities. Its high-speed data capture, consistency, and comfortable design make it invaluable for assessing comfort, fit, and safety in product development.

Using quantified data from tactile interactions is becoming standard practice in ergonomic testing. This shift allows designers to move from relying solely on subjective feelings to having concrete measurements, facilitating better design decisions and reducing the need for multiple design revisions.

Quantifying Hand Ergonomics With The Tactile Glove

Musculoskeletal disorders (MSD) are injuries or disorders of the muscles, nerves, tendons, joints and cartilage. Work-related musculoskeletal disorders (WMSD) are conditions caused, prolonged or made worse by work conditions.

Ergonomics / human factors considers the interaction between humans and other parts of a system. A goal of ergonomics is to reduce stress and eliminate injuries and disorders associated with the overuse of muscles, bad posture, and repeated tasks. A workplace ergonomics program can aim to prevent or control injuries and illnesses by eliminating or reducing worker exposure to WMSD risk factors using engineering and administrative controls. Risk factors include awkward postures, repetition, material handling, force, mechanical compression and duration of exposure.

There is strong evidence that job tasks that require a combination of risk factors (e.g., highly repetitious, forceful hand/wrist exertions) increase risk for hand/wrist tendinitis. Fifty percent of industries reported work-related musculoskeletal disorders (WMSD) rely heavily on the use of hand tools.

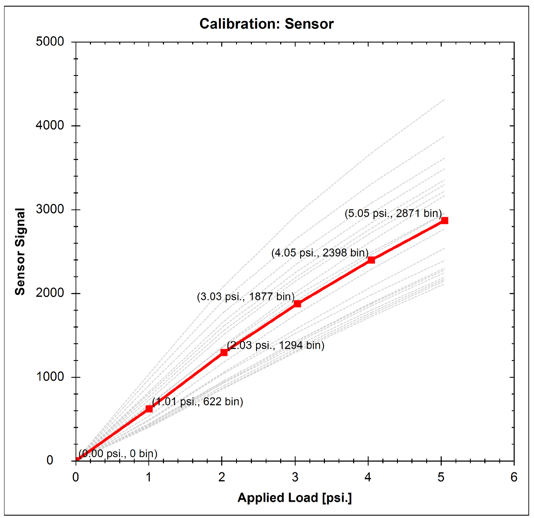

Calibrating And Verifying Tactile Pressure Sensors

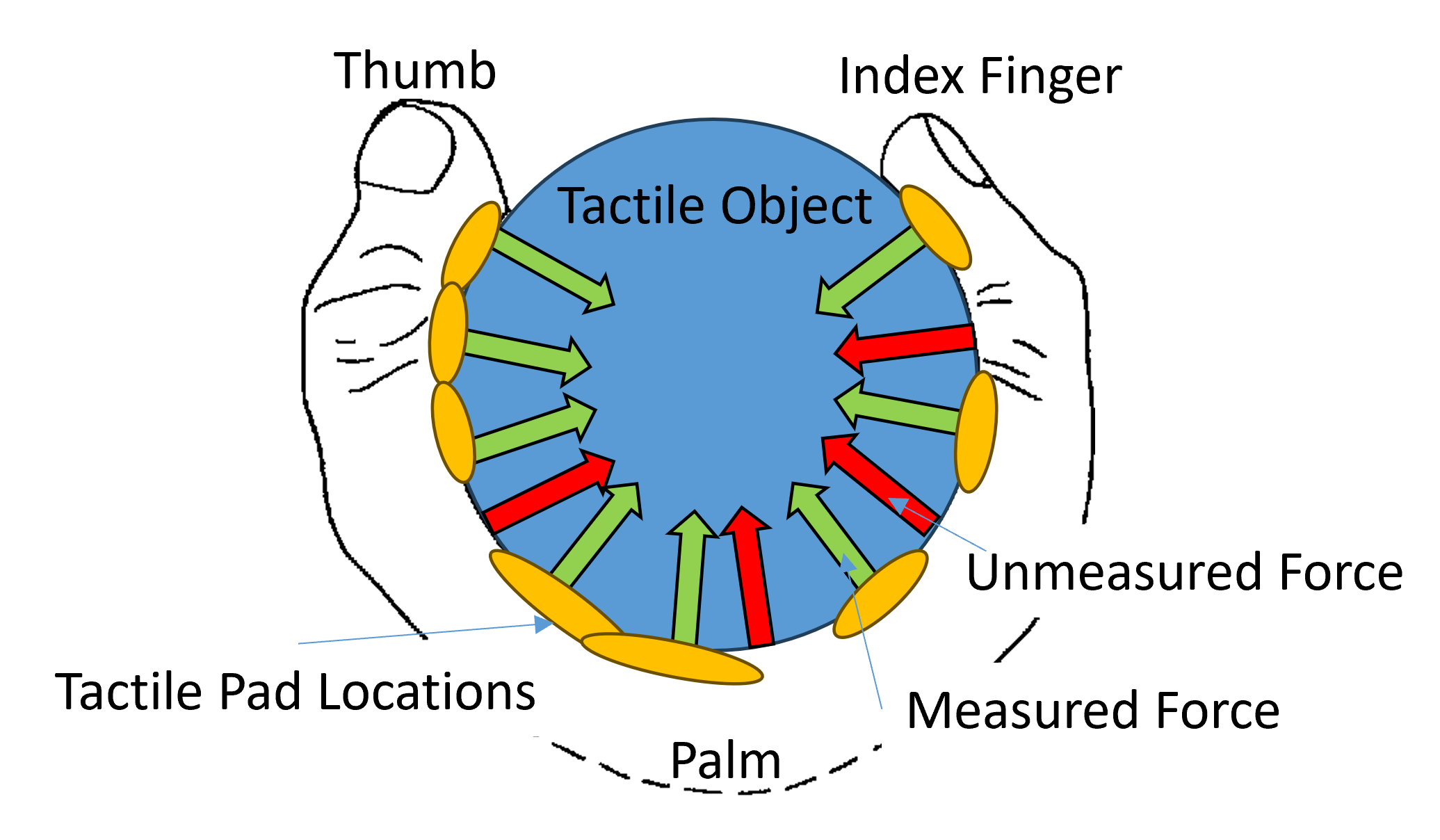

Tactile sensing involves measuring the force and pressure distributions across an area between two surfaces in direct, physical contact. However, while the common measurand terms of force and pressure may be used, the mechanics of the application are often much more complex.

Pressure is a scalar value and defined as the force over a specific area. Force can be considered a vector with a particular magnitude and direction. Traditional single axis force measurement devices such as load cells can incorporate precision flexures to concentrate the contact to a single, well-controlled point where one or more of the three directional components can be isolated and measured.

However, when considering thin and flexible tactile pressure sensors it is the interaction between the two surfaces that are trying to be captured and therefore these complex measurements must be made at the surface interaction boundary while minimizing the effect and intrusion of the sensor itself on the overall application.

This means that accurately designing, calibrating and verifying the performance of a tactile sensor is a challenging undertaking and requires careful consideration. This document is intended to serve as a guide for better understanding both the parameters that affect the calibration and that of the process and end result itself.